In the B2B manufacturing industry, having a reliable and efficient supplier for single wet wipes making machines is crucial. VIPPAI is a trusted name in the market, offering innovative solutions such as the VPD-250 single wet wipes making machine. With its advanced features and high-speed operation, this machine is designed to meet the diverse production needs of industries such as cosmetics, healthcare, and pharmaceuticals. Let's explore the unique features and benefits of the VPD-250 machine.

Unmatched Efficiency and Versatility

VIPPAI single piece wet wipes making machine is a game-changer when it comes to efficiency and versatility. It is equipped with cutting-edge technology that ensures optimal performance and seamless production processes. With a speed range of 80-110 bags per minute, this machine enables high-volume production without compromising on quality.

One of the standout features of the VPD-250 is its adjustable mold. Manufacturers can produce single piece wet tissues with dimensions ranging from (40-140) *(40-110) mm (L*W) without the need for mold changes. This flexibility saves valuable time and effort during production, allowing businesses to cater to a wide range of customer demands.

Moreover, the VPD-250 single sachet wet wipes machine offers the option to choose between single or double packs by simply replacing the dotted line knife part. This versatility in packaging options opens up new possibilities for product variations and customization, giving businesses a competitive edge in the market.

Precision and Quality Assurance

At VIPPAI, we understand the importance of maintaining the highest standards of quality in single wet wipes manufacturing. The VPD-250 machine incorporates advanced features that ensure precision and quality assurance throughout the production process.

The machine is designed to accommodate different types of non-woven fabrics, allowing for up to 10 vertical folds and 4 horizontal folds. Manufacturers have the flexibility to adjust the width and length of the non-woven fabric, achieving the desired folding pattern for their specific product requirements. This precision folding capability guarantees consistency and uniformity in the final wet wipes.

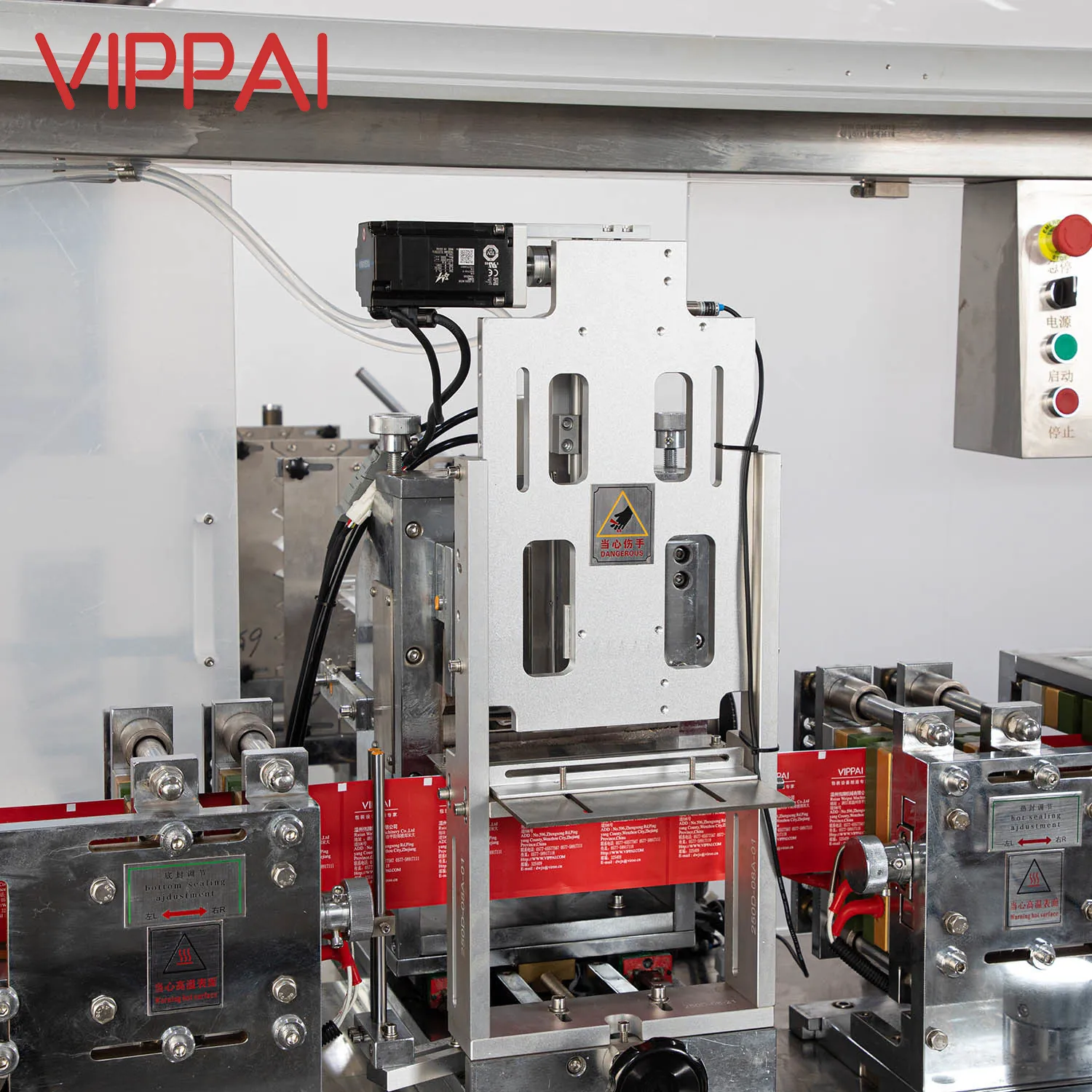

To ensure the integrity and safety of the wet wipes, the VPD-250 machine features two heat seals. These seals effectively prevent any liquid leakage, providing peace of mind to both manufacturers and end consumers. The machine's intelligent touch screen and servo motor control system further enhance the precision and accuracy of the sealing process, resulting in high-quality, leak-proof wet wipes.

Conclusion

VIPPAI's VPD-250 one piece wet wipes making machine is a game-changer in the B2B manufacturing industry. With its unmatched efficiency, versatility, and precision, this machine empowers businesses to meet the diverse demands of the cosmetics, healthcare, and pharmaceutical sectors. The adjustable mold feature, high-speed operation, and customizable packaging options make it a valuable asset for manufacturers seeking to optimize their production processes and stay ahead in a competitive market.

At VIPPAI, we are committed to providing exceptional after-sales service and technical support to our partners. From comprehensive usage guidance to reliable warranty coverage and professional technical assistance, we ensure that our customers receive the support they need throughout their wet wipes manufacturing journey.

Choose VIPPAI as your trusted partner for wet wipes making machines, and experience the benefits of streamlined production, superior quality, and efficient operations. Contact us today to learn more about the VPD-250 machine and how it can revolutionize your wet wipes manufacturing process.