Are you in the medical, household goods, or pharmaceutical industry and in need of reliable and efficient packaging machines for swabs? Look no further than VIPPAI and our cutting-edge VPD-800 Alcohol Swab Machine. In this article, we will delve into the key components and functionality of this advanced machine, highlighting its outstanding features and how it can benefit your business.

Packaging Film and Non-woven Rolls

When it comes to packaging swabs, the quality and precision of the packaging film are crucial. Our VPD-800 Alcohol Swab Machine boasts a dedicated part called the Package Film, ensuring the optimal placement and protection of the swabs. Additionally, the Non-woven Rolls part allows manufacturers to choose between eight small rolls or one big roll cut into eight rolls, providing flexibility and customization options to suit your specific requirements.

Automatic Slitting and Deviation Correction

Efficiency and accuracy are at the heart of our VPD-800 Alcohol Swab Machine. With the Automatic Slitting Part, the machine automatically cuts one large non-woven fabric roll into eight rolls, streamlining the production process. Furthermore, the Deviation Correction and Photoelectric Eye Monitoring part, equipped with Japan Panasonic photoelectric eye detection technology, ensures precise and error-free film cutting. By utilizing this advanced feature, you can rest assured that your swabs will be packaged flawlessly.

Essence Adding and Sealing Process

At VIPPAI, we understand the importance of precise liquid volume control when adding alcohol essence to swabs. That is why our VPD-800 Alcohol Swab Machine incorporates the innovative Essence Adding part, which utilizes a Swiss Gotec Electromagnetic Pump. This pump not only ensures high accuracy but also boasts strong corrosion resistance, guaranteeing the longevity and reliability of the machine. Additionally, our Four-side Sealing feature ensures precision heat sealing, providing optimal protection for your swabs.

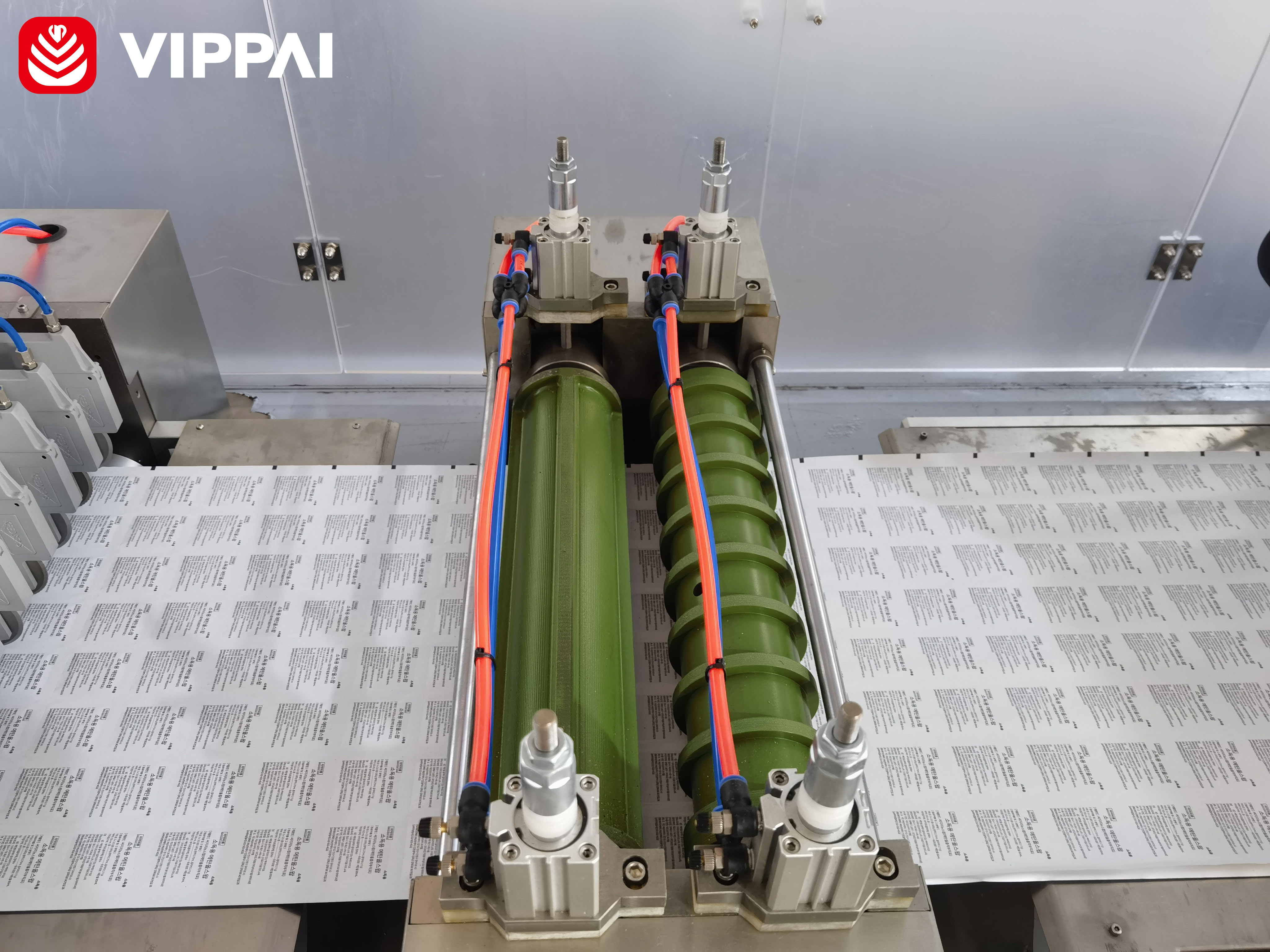

Slitter System for Cutting Alcohol Swabs

To meet the demands of high-volume production, our VPD-800 Alcohol Swab Machine is equipped with a state-of-the-art Slitter System. This system efficiently cuts alcohol swabs into eight pieces, maximizing productivity and output. With this capability, you can significantly increase your production capacity to meet the needs of your customers.

Conclusion

When it comes to VIPPAI packaging machines for swabs, VIPPAI's VPD-800 Alcohol Swab Machine is the ultimate choice. The machine's key components and functionality, including the Packaging Film and Non-woven Rolls, Automatic Slitting and Deviation Correction, Essence Adding and Sealing Process, and Slitter System, ensure exceptional performance and reliability. By investing in our products, you can enhance your production efficiency, deliver top-quality swabs to your customers, and stay ahead of the competition. At VIPPAI, we take pride in our commitment to providing outstanding products and services. Our company is dedicated to supporting our customers with reliable after-sales service, technical assistance, and a one-year warranty on all electrical parts. When you choose VIPPAI, you choose excellence and a partner who is fully invested in your success. Contact us today to learn more about our VPD-800 Alcohol Swab Machine and how it can transform your business.