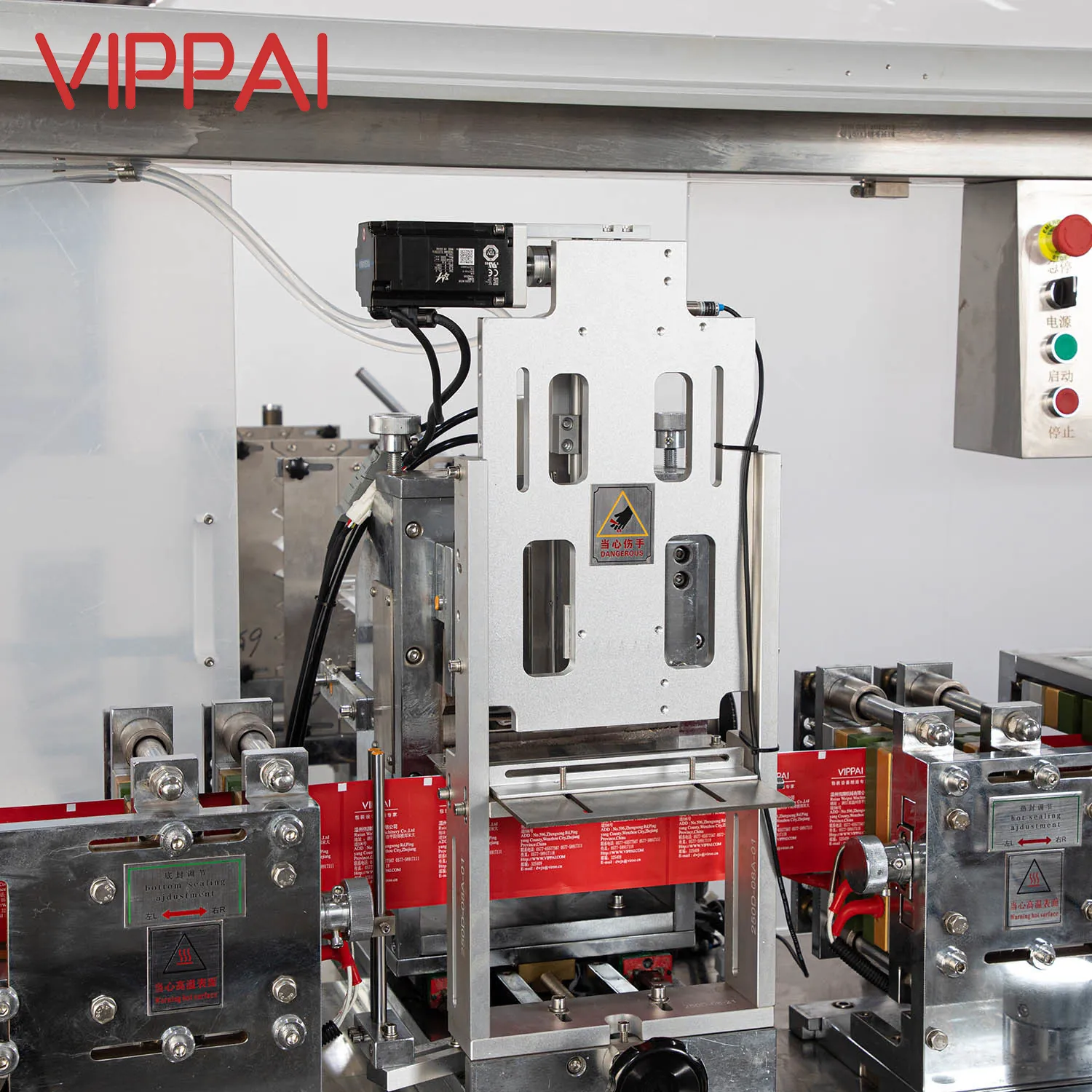

Introducing Vippai wet wipes manufacturing machine , an incredible invention in the world of hygiene. With its innovative four-side sealing design, this cutting-edge wet wipes manufacturing machine sets a new standard for efficiency and effectiveness. Say goodbye to flimsy wipes and hello to a superior cleaning experience with Vippai like never before. Join us as we delve into the remarkable features and benefits that make the VPD-250 machine a must-have for businesses and households alike. Prepare to be amazed!

Advantages of the VPD-250's Four-Side Sealing Design

Our VPD-250's four-side sealing design is one of its most notable features that sets it apart from other wet wipes machines in the market. This innovative design offers a range of advantages that make it a preferred choice for manufacturers looking to improve their production processes and increase efficiency.

- Improved Product Quality:

One of the main advantages of the VPD-250's four-side sealing design is that it ensures consistent and uniform sealing on all four sides of the wet wipes packet. This not only enhances the overall appearance of the product, but also minimizes the risk of leakage or contamination during storage or transport. With this machine, manufacturers can be assured that every single wipe produced will be sealed securely and maintain its freshness until it reaches consumers.

- Increased Production Speed:

The four-side sealing design also allows for faster production speeds compared to traditional three-side sealing machines. This is because all four sides are sealed simultaneously, reducing cycle time and increasing output. The VPD-250 has a maximum speed of 120 packs per minute, making it one of the fastest wet wipes machines in its category.

- Versatility:

Another advantage of the VPD-250's four-side sealing design is its versatility in handling various types and sizes of wet wipes packaging materials. From plastic film to non-woven fabric, this machine can accommodate different materials without compromising on quality or speed. It can also produce packets in different sizes ranging from mini travel packs to larger family-sized packs.

Comparison with Other Wet Wipe Machines on the Market

- Traditional Single-Side Sealing Machines:

The most common type of wet wipe machine is a traditional single-side sealing machine. These machines use a horizontal or vertical sealing method to seal one side of the wipes. While these machines are widely available and relatively affordable, they have some limitations when it comes to producing high-quality wipes.

- Three-Side Sealing Machines:

Three-side sealing machines are an improvement over traditional single-side sealing machines as they seal three sides of the wipes instead of just one. This allows for more precise cutting and eliminates the gap between wipes mentioned above.

Conclusion

With its innovative four-side sealing design, the VPD-250 General Speed Right Angle Wet Wipes Machine sets a new standard for efficiency and quality in wet wipe production. This machine not only increases production speed but also ensures that each wipe is fully sealed to maintain freshness and hygiene. Its user-friendly interface and customizable options make it a top choice for manufacturers looking to streamline their process and produce high-quality products. Our VPD-250 is truly transforming the wet wipes industry and setting a new standard of excellence.