As the demand for eye patches continues to surge in the pharmaceutical, personal care, and beauty industries, packaging manufacturers are seeking innovative solutions to meet the growing market needs. In response to this demand, Vippai, a leading brand in the automatic packaging machine industry, has introduced its cutting-edge VPD800E Eye Patches Packing Machine. With a strong focus on high-speed capabilities and superior quality seals, Vippai automatic packaging machine VPD800E is set to revolutionize the way gel-based eye patches are packaged, providing manufacturers with an unparalleled edge in the competitive market.

The Power of High-Speed Technology

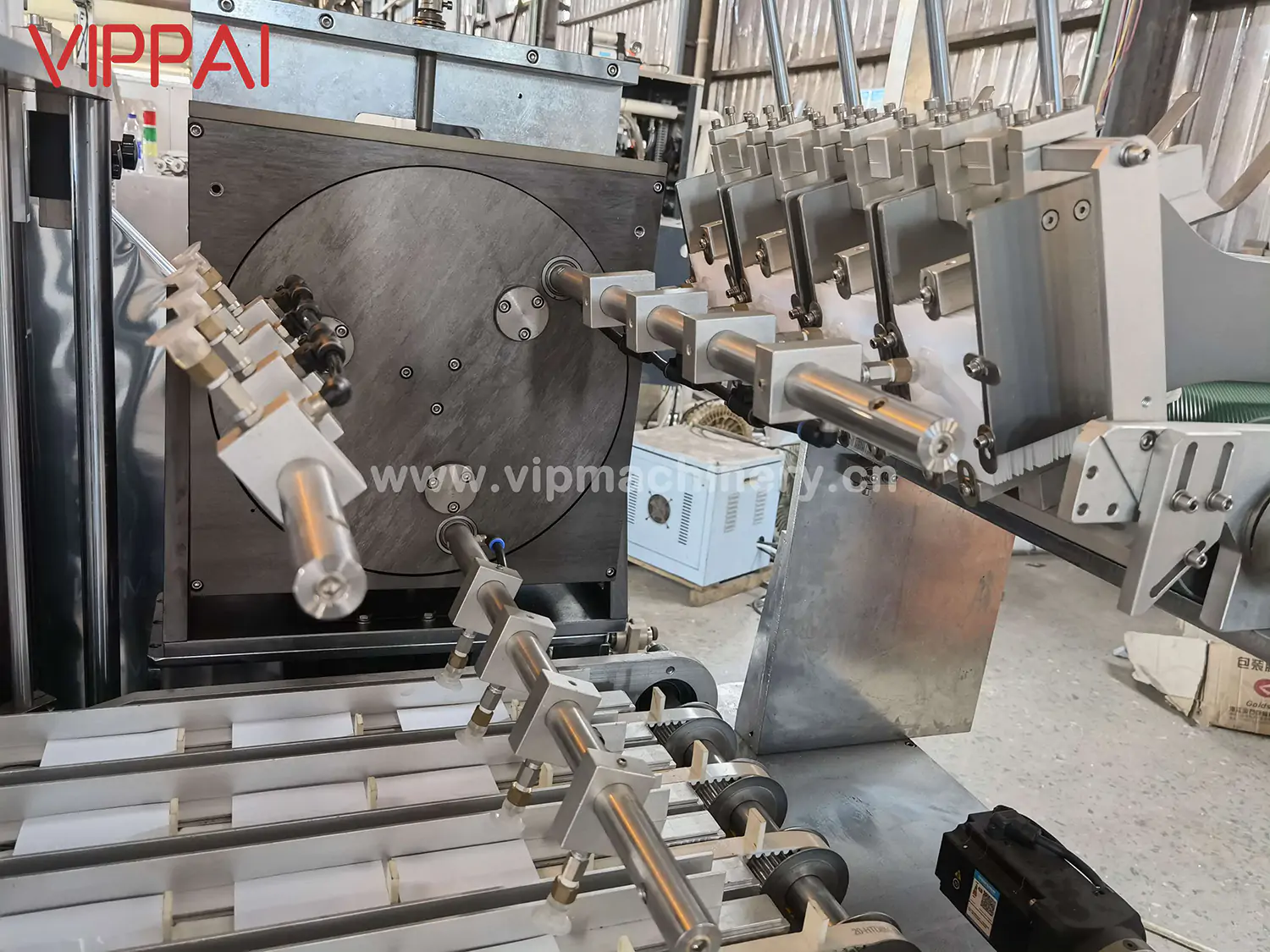

The VPD800E Eye Patches Packing Machine boasts an impressive packaging speed ranging from 500 to 1000 bags per minute, making it a true game-changer for eye patch manufacturers. This remarkable speed allows for a substantial increase in productivity, leading to significant cost savings and quicker turnaround times. By effortlessly outputting 4 bags at once, this high-speed machine ensures efficient and streamlined packaging operations, giving manufacturers a competitive advantage in meeting market demands.

Unmatched Sealing Excellence

A critical aspect of eye patch packaging is the seal quality, as it directly impacts product freshness, shelf life, and customer satisfaction. Vippai's VPD800E incorporates a reciprocating heat sealing mechanism that optimizes sealing efficiency. The design provides sufficient sealing time for large-area seals, resulting in strong, smooth, and visually appealing packaging. This sealing mechanism accommodates a wide range of packaging materials, including composite films, aluminized films, and polyethylene/polypropylene, offering manufacturers the flexibility to choose the most suitable materials for their eye patches.

Moreover, the machine's ability to handle non-woven fabrics as inner materials for the gel eye patches ensures that the packaging maintains the product's integrity while preserving its therapeutic properties. This ensures the end consumers receive eye patches in pristine condition, thereby enhancing brand loyalty and customer trust.

Intelligent Features for Optimal Efficiency

Vippai's VPD800E Eye Patches Packing Machine comes equipped with intelligent features that enhance overall efficiency and ease of operation. The machine is powered by Yaskawa servo motors, renowned for their reliability and precise control. The user-friendly touch screen interface allows operators to adjust parameters effortlessly, ensuring safe and consistent text writing control.

Incorporated within the machine are automatic error detection and correction systems. The VPD800E automatically alerts operators of any film shortage and halts the operation to prevent potential packaging issues. Furthermore, the machine's two-cursor point tracking system enables automatic calibration, generating seamless and stable seals, eliminating potential wastage of packaging materials and minimizing production downtime.

Conclusion

In the dynamic landscape of eye patch manufacturing, Vippai's VPD800E Eye Patches Packing Machine has emerged as a true industry leader, empowering manufacturers with its high-speed capabilities and unmatched sealing excellence. By revolutionizing the packaging process, this cutting-edge machine not only enhances productivity but also guarantees the integrity and freshness of gel-based eye patches. With Vippai's commitment to innovation and advanced technology, the VPD800E paves the way for a more efficient, competitive, and successful future in the eye patch market.