In the competitive world of cosmetic manufacturing, efficient packaging plays a vital role in capturing consumers' attention and ensuring product quality. We, VIPPAI, a trusted name in the industry, are delighted to present the VIPPAI packing machine for cosmetic facial mask. This state-of-the-art packaging solution is designed to streamline the packaging process, optimize productivity, and maintain the integrity of your cosmetic facial masks. Let's delve into the features and benefits of the VIPPAI packing machine for cosmetic facial mask.

Advanced Packaging Technology

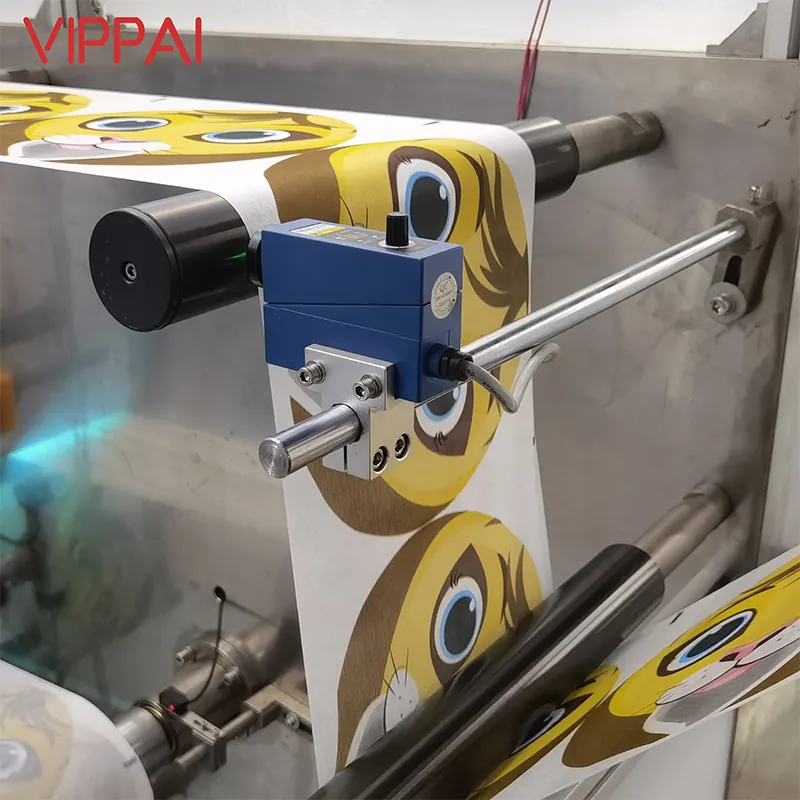

Our Cosmetic Facial Mask Packing Machine is equipped with cutting-edge technology that meets the stringent requirements of GMP-certified production equipment. This machine integrates multiple functions, including roll film feeding, film cutting and forming, mask folding, bag making (or using prefabricated bags), essence liquid pouring, bag sealing, and more. By replacing traditional manual workshop production equipment such as punching machines, forming machines, folding machines, and sealing machines, our packaging machine offers a comprehensive and efficient solution for your packaging needs.

Labor and Cost Savings

With our Cosmetic Facial Mask Packing Machine, you can significantly reduce labor costs and enhance operational efficiency. By automating the packaging process, this machine eliminates the need for 8-15 manual laborers, allowing you to allocate resources more effectively. Moreover, the machine optimizes the use of packaging materials, resulting in cost savings of up to 20-30%. By streamlining production and reducing expenses, you can improve your bottom line and stay ahead of the competition.

Product Quality and Hygiene

Maintaining the quality and hygiene of your cosmetic facial masks is paramount to meeting customer expectations. Our Cosmetic Facial Mask Packing Machine ensures product integrity by completing the entire packaging process within a sealed environment. This eliminates the risk of contamination and secondary pollution, safeguarding the quality and efficacy of your products. With our commitment to GMP standards, you can have peace of mind knowing that your cosmetic facial masks are packaged in a controlled and hygienic environment.

Versatility and Precision

Our packaging machine offers easy adjustment for different bag types, accommodating a wide range of packaging requirements. Whether you need various sizes or designs, the VIPPAI Cosmetic Facial Mask Packing Machine can adapt to your specific needs. The machine's servo setting allows for precise and stable operation, ensuring consistent packaging quality. Additionally, the high-end metering pump filling system provides exceptional accuracy, with a precision of plus or minus 1 gram, guaranteeing precise and reliable filling of the essence liquid.

Superior After-sales Support

At VIPPAI, we prioritize the success of our customers. Along with delivering top-notch packaging solutions, we offer comprehensive after-sales service and technical support. When you acquire the VIPPAI Cosmetic Facial Mask Packing Machine, we provide installation guidance, operational training, and detailed manuals to ensure a smooth integration into your production line. Moreover, our one-year warranty covers all electrical parts, and our dedicated team of engineers is ready to provide prompt online assistance or arrange for on-site repairs if necessary.

Conclusion

The VIPPAI Cosmetic Facial Mask Packing Machine empowers you to enhance your packaging efficiency, reduce costs, and deliver high-quality cosmetic facial masks to your customers. With its advanced technology, labor-saving features, and commitment to product integrity, our packaging machine is the ideal choice for cosmetic manufacturers seeking a competitive edge. Trust VIPPAI to be your reliable partner in optimizing your packaging process and achieving success in the cosmetic industry.