When it comes to enhancing your cosmetics production, VIPPAI's facial mask filling and sealing machine is a game-changer. With its streamlined operation process, you can achieve efficient and high-volume production.

Loading Pre-Made Bags into the Hopper

Our facial mask machine simplifies the production process by allowing you to easily load pre-made bags into the hopper. This eliminates the need for manual bag preparation, saving you time and effort.

Robot Arm Bag Picking and Opening

Using advanced technology, our machine features a robot arm that precisely picks and opens the bags. This automation ensures accuracy and consistency, reducing the risk of errors during the production process.

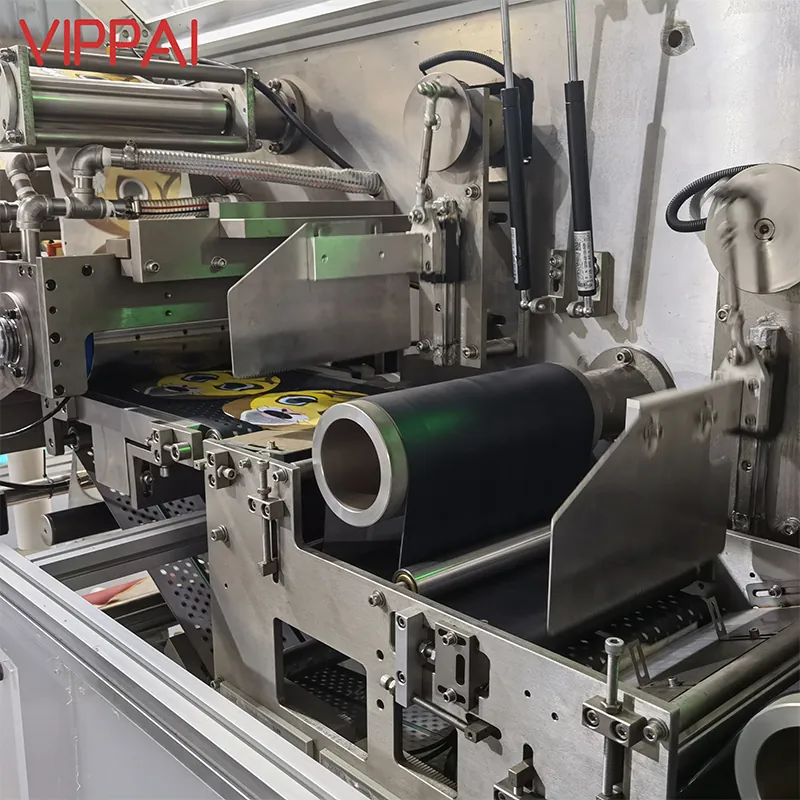

Bag Top Side Sealing, Liquid Filling, and Embossing

VIPPAI's facial mask filling and sealing machine seamlessly performs bag top side sealing, liquid filling, and embossing. The machine is equipped with state-of-the-art components and mechanisms to ensure precise and reliable results every time.

Diverse Compatibility with Packing Materials

At VIPPAI, we understand that different cosmetics manufacturers may have varying preferences for packing materials. That's why our VIPPAI facial mask machine offers diverse compatibility to meet your specific needs. Our machine is designed to work with a wide range of packing materials, including CPP, PE, PET, BOPP compound film, aluminum foil film, and paper film. This versatility allows you to choose the material that best suits your product and branding requirements.

Packing Material Size Range

With VIPPAI's facial mask machine, you have the flexibility to accommodate various packing material sizes. Whether you need smaller or larger packaging, our machine can handle it with ease, providing you with the freedom to customize your product offerings.

Liquid Filling Capacity with High Accuracy

To ensure precision and consistency in your cosmetics production, our machine offers a high liquid filling capacity with exceptional accuracy. You can trust that each mask will be filled with the perfect amount of liquid, maintaining the quality and efficacy of your products.

User-Friendly Design and Quality Assurance

VIPPAI takes pride in delivering user-friendly machines that prioritize both efficiency and quality. Our facial mask filling and sealing machine is designed with your convenience and product integrity in mind.

304 Stainless Steel Construction, Compliant with GMP Standards

To meet the highest standards of hygiene and durability, our machine is constructed with 304 stainless steel. This material ensures easy cleaning and maintenance, allowing you to maintain a sanitary production environment. Our machine is also compliant with GMP (Good Manufacturing Practice) standards, guaranteeing the quality and safety of your cosmetic products.

Sensor-Based Bag Opening Verification

Ensuring the integrity of each bag is crucial in the cosmetics industry. That's why our machine utilizes sensor-based bag opening verification. It verifies that each bag is properly opened before the filling and sealing process, minimizing the risk of faulty packaging and product waste.

Heat Seal Device with Teflon Coating for Excellent Seal Performance

The heat seal device of our facial mask machine is equipped with a Teflon coating, which offers excellent seal performance. This feature guarantees a strong and secure seal, preventing any leakage or contamination of your products. With VIPPAI's machine, you can have full confidence in the quality of your sealed facial mask packages.

Conclusion

In conclusion, VIPPAI's facial mask filling and sealing machine is a reliable solution to enhance your cosmetics production. With its streamlined operation process, compatibility with diverse packing materials, and user-friendly design, our machine empowers you to achieve efficient and high-quality production. Experience the benefits of VIPPAI and join our satisfied customers who have already revolutionized their cosmetics manufacturing with our state-of-the-art machines.